Explore our portfolio of cutting-edge electronics manufacturing projects. From rapid prototyping to high-volume production, we deliver precision, quality, and innovation across every industry.

Industry-leading manufacturing capabilities backed by decades of experience and cutting-edge technology

24-48 hour turnaround for prototype PCB assembly and testing

ISO 9001, ISO 14001, and RoHS compliant manufacturing processes

20+ years serving aerospace, medical, automotive, and industrial sectors

Trusted by Fortune 500 companies and innovative startups worldwide

Real-world examples of our manufacturing excellence across diverse industries and applications

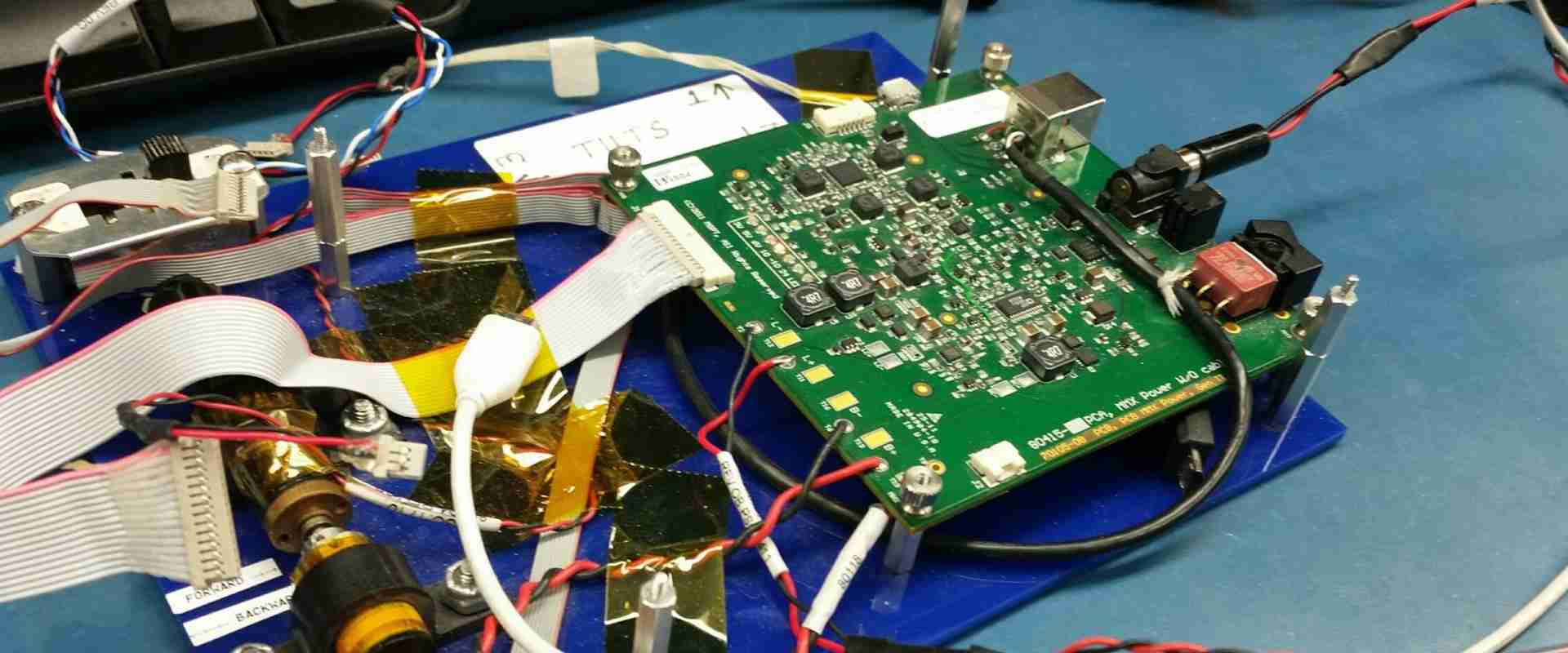

Complex multi-layer PCB prototype with integrated power management, multiple ribbon cable connections, and advanced testing protocols. Delivered rapid prototyping with full functional testing within 48 hours.

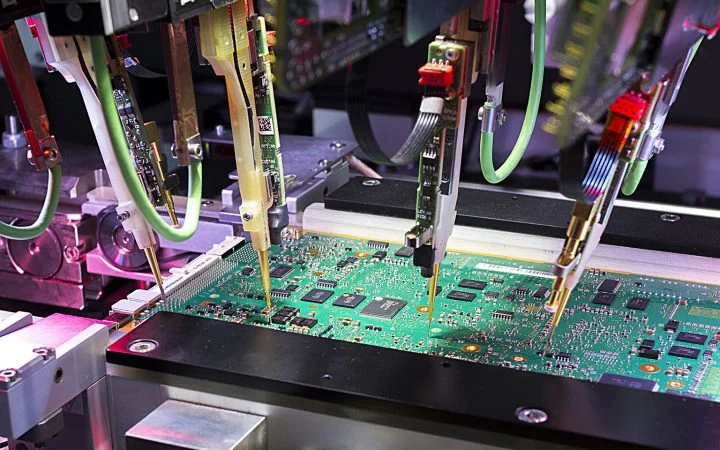

State-of-the-art automated assembly line featuring robotic soldering, precision component placement, and real-time quality control. Capable of producing 10,000+ units per day with 99.9% accuracy.

Precision-engineered wire harness assemblies with custom connectors, color-coded wiring, and rigorous testing. Designed for harsh environments with IP67 protection and military-grade specifications.

High-performance multi-conductor cables with shielded construction, precision termination, and extensive testing. Suitable for high-frequency applications and industrial environments.

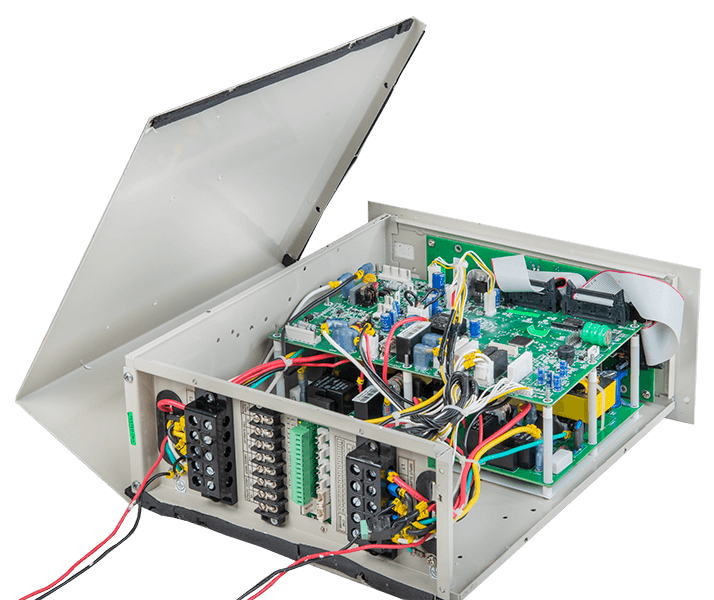

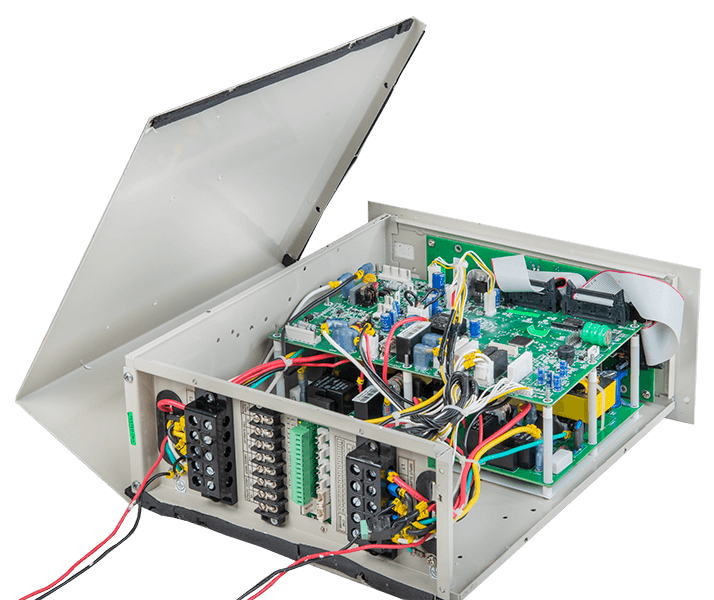

Full system integration including PCB assembly, mechanical housing, power supplies, and final testing. Complete turnkey solution from component sourcing to final product delivery.

Comprehensive testing protocols including AOI, X-ray inspection, functional testing, and burn-in testing. ISO 9001 certified processes ensuring the highest quality standards.

From concept to delivery, we follow a proven process that ensures quality at every step

Expert DFM analysis and design optimization to ensure manufacturability and cost-effectiveness

Rapid prototyping with comprehensive testing protocols to validate design and functionality

Automated assembly lines with real-time quality control for consistent, high-volume production

Multi-stage inspection including AOI, X-ray, and functional testing to ensure zero defects

Complete box build and system integration with meticulous attention to detail

On-time delivery with comprehensive documentation and ongoing technical support

Join hundreds of satisfied clients who trust us with their electronics manufacturing needs. Get a free quote today and experience the Jayshree Instruments difference.