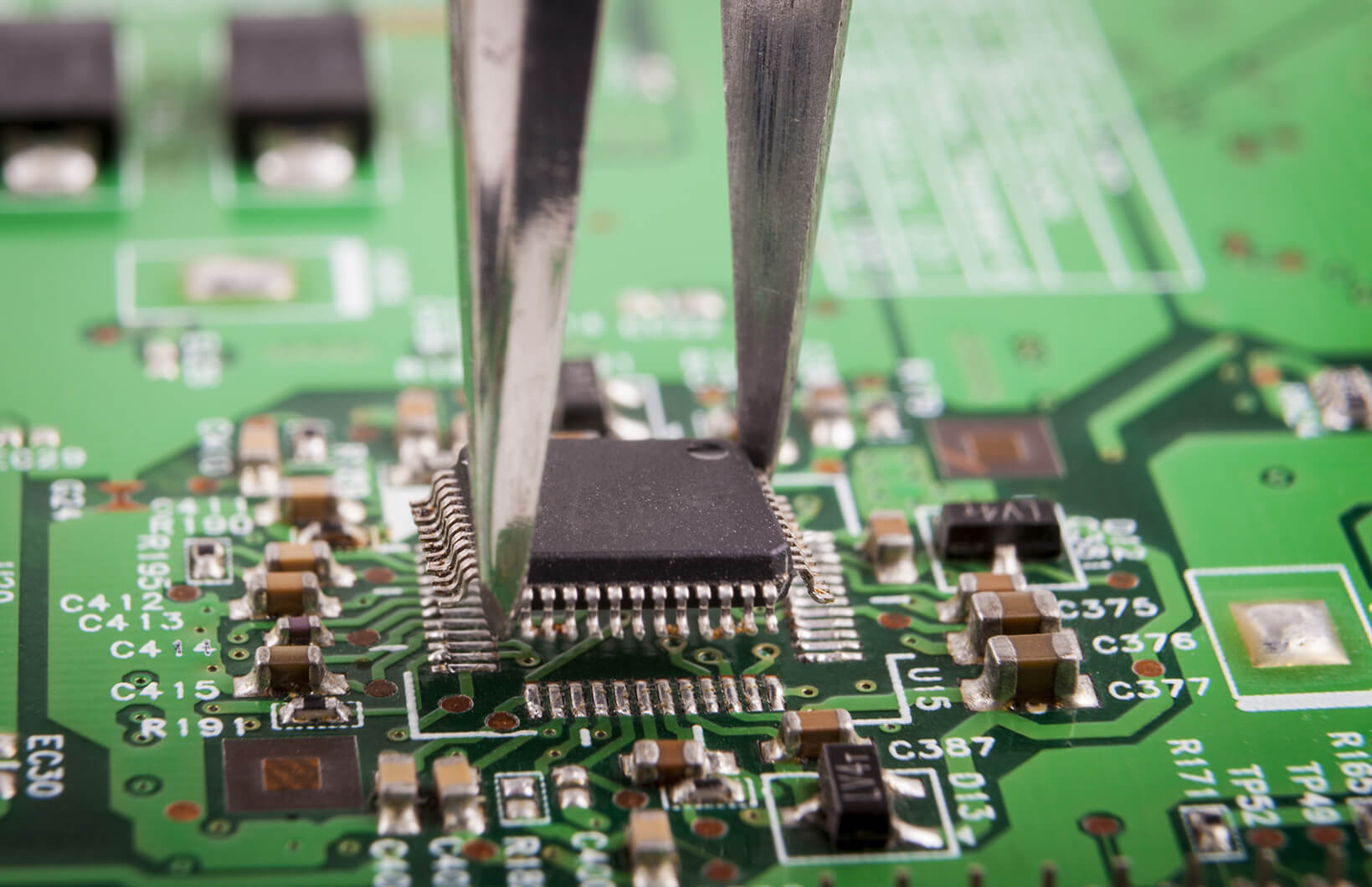

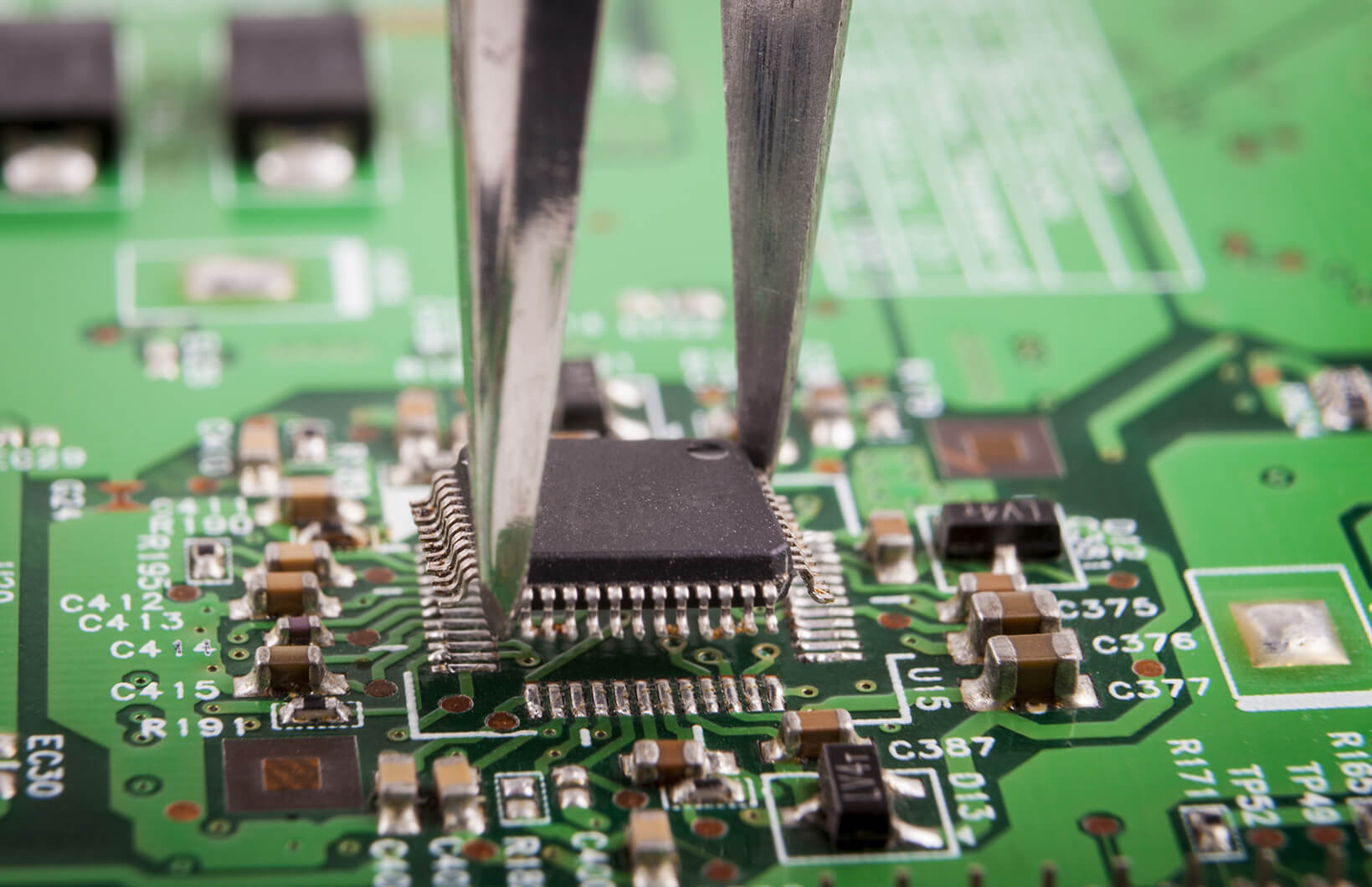

See Our PCB Assembly Process in Action

Watch how we transform your designs into high-quality assembled PCBs

What We Do

Our PCB assembly services combine cutting-edge technology with decades of manufacturing expertise. We handle everything from simple single-layer boards to complex multi-layer assemblies with fine-pitch components.

With state-of-the-art SMT lines, automated optical inspection, and X-ray capabilities, we ensure every board meets the highest quality standards. Our team of certified IPC specialists oversees every step of the assembly process.

Industry-Specific Solutions

Specialized expertise and compliance certifications for every industry

Automotive

AEC-Q200 compliant assemblies for automotive electronics

Medical Devices

ISO 13485 certified for medical-grade PCB assembly

Industrial IoT

Rugged assemblies for harsh industrial environments

Consumer Electronics

High-volume production with competitive pricing

Telecommunications

High-reliability assemblies for telecom infrastructure

Aerospace & Defense

AS9100 certified for aerospace applications

Maximize Efficiency & Reduce Costs

Our advanced manufacturing processes and global supply chain partnerships enable us to deliver cost-effective solutions without compromising quality. We optimize every aspect of production to maximize your ROI.

Design for Manufacturability (DFM) optimization

Bulk component purchasing discounts

Efficient production scheduling

Waste reduction through lean manufacturing

Flexible volume pricing models

Our PCB Assembly Process

A streamlined 6-step process ensuring quality at every stage

Design Review

Comprehensive DFM analysis and design optimization for manufacturability.

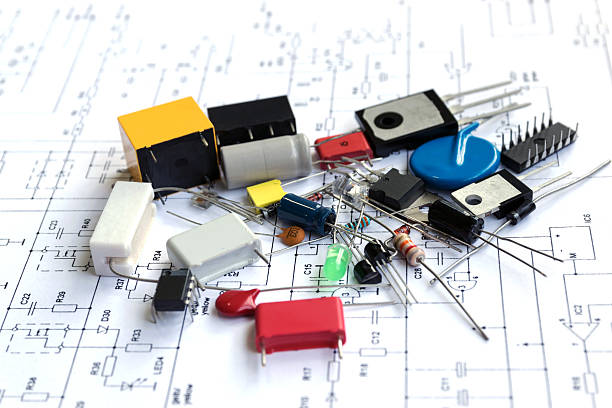

Material Procurement

Sourcing high-quality components from verified suppliers worldwide.

SMT Assembly

Automated pick-and-place with precision solder paste application.

Reflow Soldering

Controlled reflow process ensuring perfect solder joints.

Inspection & Testing

AOI, X-ray inspection, and functional testing for quality assurance.

Delivery

Secure packaging and on-time delivery to your location.

Advanced Technology & Equipment

State-of-the-art machinery ensuring precision and quality

High-Speed SMT Lines

Latest generation pick-and-place machines with 0201 component capability

X-Ray Inspection

Advanced X-ray systems for BGA and hidden solder joint inspection

AOI Systems

3D automated optical inspection for comprehensive quality control

Reflow Ovens

Precision temperature-controlled reflow ovens with nitrogen atmosphere

What We Offer

Comprehensive PCB assembly services tailored to your specific requirements

Surface Mount Technology (SMT)

High-speed automated SMT assembly with precision placement for complex boards.

Through-Hole Assembly

Traditional through-hole assembly for components requiring mechanical strength.

Mixed Technology Assembly

Combining SMT and through-hole techniques for optimal board design.

BGA and Micro-BGA Assembly

Advanced ball grid array assembly with X-ray inspection capabilities.

Lead-Free and RoHS Compliant

Environmentally friendly assembly meeting global compliance standards.

Automated Optical Inspection (AOI)

State-of-the-art AOI systems ensuring zero-defect manufacturing.

.jpg)

Rigorous Quality Control

Every PCB assembly undergoes multiple quality checkpoints throughout the manufacturing process. Our comprehensive QC procedures ensure zero-defect delivery.

Incoming component inspection and verification

In-process AOI and X-ray inspection

Functional testing and burn-in procedures

Final visual inspection and packaging